- Environmental benefits of RMC products

- Resource reduction

- Recycling

- Reuse

- Health

- Safety

- Ethical Conduct

- Community Outreach

- Energy savings

- Weight reduction

- Durability

- Processing efficiency

- Reduced maintenance

Sustainability

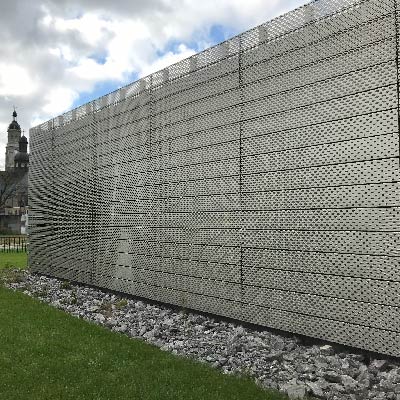

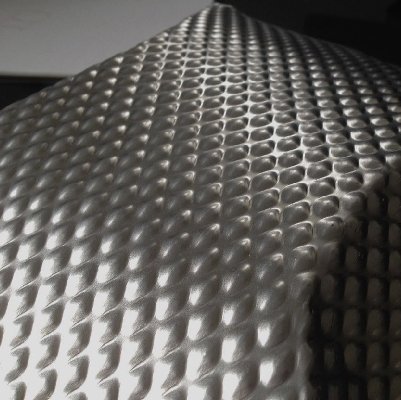

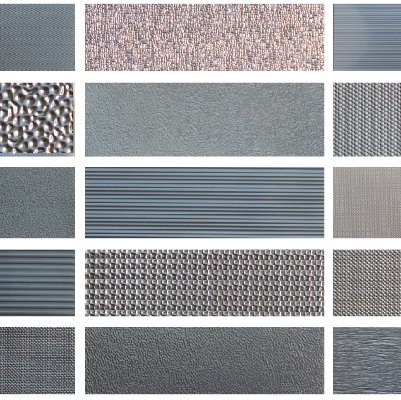

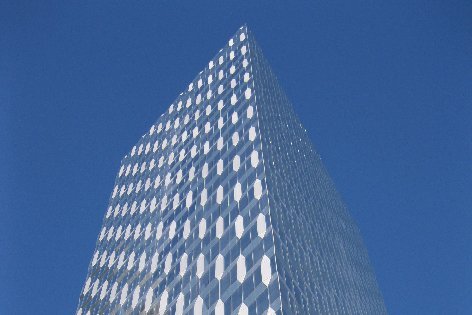

Rigidized® Metals products are a great marriage of beauty and utility. Textured stainless steel is playing an important role in sustainable design and alternative energy evolution. Ultimately, the most environmentally friendly materials are corrosion-resistant and durable, have high recycled content and recapture rates, provide long service life and reduce resource use. Rigidized® Metals engineered surfaces provide all of these benefits. If the correct alloy is selected and properly maintained, it will last the life of the project.

Providing sustainable products and services is at the forefront of our business goals. Not only are we focusing on making our products and services more sustainable on all fronts, our employees are also continuously striving to make our world a more sustainable place. Learn about what the RGDZRs are doing to make Rigidized® Metals more sustainable.

How can Rigidized® Metals Support Your Sustainability Goals?

Architecture

Compared to many other materials, metals have relatively low embodied energy. Perhaps more importantly, properly specified metal materials can reflect solar radiation, making buildings more efficient, as well as making urban environments, and the planet as a whole, cooler. Health and safety are also supported by proper metal material selection. Low life cycle costs are the result of specifying materials that will last the useful life of the building, without requiring replacement or significant amount of maintenance.

Material Handling Equipment

Low friction surfaces can make goods flow more easily improving the efficiency of operations. Less metal can be used by adding an engineered surface design to a base material specification. Durability of these surfaces can be engineered as well, reducing the frequency at which you need to replace material handling components.

Transportation and Automotive

The weight reduction advantages of engineered metal surfaces can improve the efficiency of vehicles traveling by land, sea or air. Further, metal components can contribute to engine or battery performance, promoting their efficiency as well.

Food Service Equipment

Hygienic food contact surfaces can be optimized. Efficiency in refrigeration and dispensing food products at the manufacturing and consumer levels can be improved as well.

Heat Exchangers & HVAC Equipment

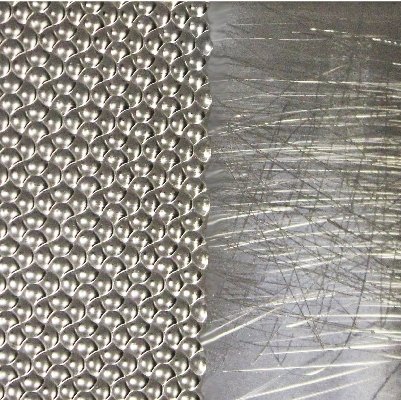

Enhanced surface tubing allows heat exchanges to operate more efficiently, using less energy and potentially less material to build a heat exchanger in the first place. We can help you optimize the amount of heat you move for the amount of resources employed in the process.

Batteries

Electrode surfaces in battery applications can be optimized by metal surface design that improve their efficiency, allowing them to charge more rapidly and extend the interval between charges.

Rigidized® Metals products are covered by EPD and HPD documents that have been third-party verified, in accordance with LEED Version 4, as well as other environmental bodies. A Life Cycle Assessment (LCA) report is available upon request. Learn more here.

Click here to request a consultation with a Rigidized® Metals expert who can help you find opportunities to make your product or project more sustainable.

Sustainability Documentation

Explore additional benefits of Rigidized® Metals’ engineered surfaces.