Joinery Methods

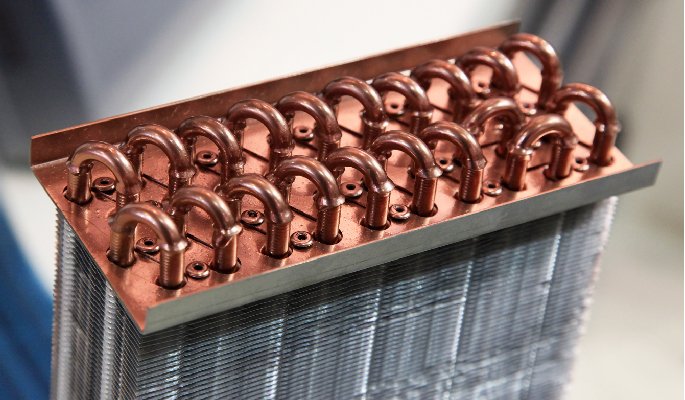

Vipertex® enhanced surfaces are produced in a variety of alloy systems, which individually lend themselves to processes such as welding, brazing, soldering, etc. While we will not go into detail about the merits of each of these hot processes in various metals, be assured that Vipertex® patterns are embossed into the parent metal and conform to your expectations regarding the alloy from which a particular Vipertex® product is made.

Vipertex® tubes are produced from pre-textured strip and will have enhanced pattern from end to end. In our experience, most heat exchanger operations are able to overcome ends with these surface patterns with procedures conducted in-house. For cases where this is not readily solved in the customer’s shop, we are able to condition the ends to remove the textured pattern for ready introduction to the customer’s operation at added cost.

Vipertex® tubes are produced from pre-textured strip and will have enhanced pattern from end to end. In our experience, most heat exchanger operations are able to overcome ends with these surface patterns with procedures conducted in-house. For cases where this is not readily solved in the customer’s shop, we are able to condition the ends to remove the textured pattern for ready introduction to the customer’s operation at added cost. Below is a video demonstration on how this process is done.

Fabrication Benefits

- Tightly-wound enhanced coil sections – it is possible to have tight geometry with Vipertex® tube arrays. It is often necessary to allow larger return radii in the case of finned tubes.

- Tubes & flat-rolled shipable in coil form – enhanced tubes can be produced in large coils, adding flexibility for downstream applications and installations. Likewise, flat goods are also produced in coil, optimizing Vipertex® for efficient stamping operations that produce a large number of parts.

- More homogeneous properties are present since Vipertex® tubes are annealed after the surface pattern is imparted.

- Scalability – our ability to produce large quantities of enhanced surface material rapidly gives Vipertex® an advantage in high-volume manufactured parts, as well as large scale projects, that can challenge capacity to produce enhanced surfaces in the conventional manner.

- Vipertex® tubes bend more gracefully, exhibiting less wrinkling than smooth tubes. This is a result of the complex surface pattern, allowing metal to flow in more directions during the bending process. The bent sections of Vipertex® tubes are stronger and present less restriction of the fluid flow within the tube. This presents an opportunity, in some cases, to reduce wall thickness and design a tighter bend radii.

Learn more about Vipertex®, here.