Retrofitting with Vipertex® to Resolve Bottlenecks

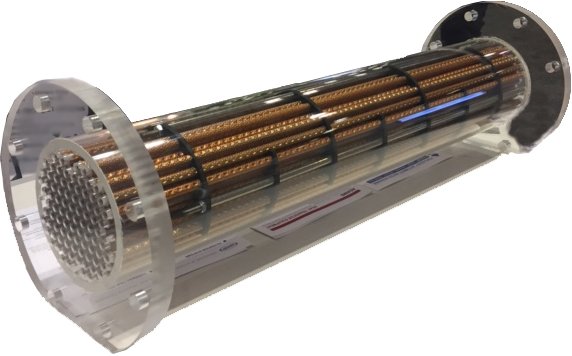

A common thread that exists within the process industries is the reality of bottlenecks. Despite the best planning, process manufacturing operations, over time, experience changes in product mix and improvements in individual unit efficiency that create a situation where a given process unit becomes the pinch point that limits the facility’s output. By definition, a bottleneck is created.

Because of the exemplary heat transfer efficiency of Vipertex® enhanced surfaces, there is an opportunity in most cases to retrofit heat exchangers with Vipertex® components to resolve bottlenecks. Theoretically, under most conditions, replacing a smooth tube with a Vipertex® tube in the heat exchanger results in twice the heat transfer.

The economic value of bottleneck resolution can be substantial. It is prudent for operators of industrial process heat exchangers, and the suppliers who build and support these installations, to investigate the value of a Vipertex® installation.

Whether you are retrofitting an existing installation or building new, let us help you determine the economic value of using Vipertex®.

Increase Output Without a Bricks and Mortar Investment

Building a new plant is a big decision that has many benefits, as well as drawbacks. On the upside, you can optimize layout and define optimal capacity, taking advantage of the latest technologies, to have a truly up-to-date, efficient facility.

On the downside, it takes a long time to take advantage of a brand new plant’s capacity and in the process industries, the permitting process can be extraordinarily complicated and time consuming. Perhaps there is an opportunity to review existing operations and consider ways to increase output within the confines of the existing facility. If heat exchangers are in the field of opportunity, as they very often are, Vipertex® can help.

Vipertex® enhanced surfaces can increase heat transfer by approximately 100% when compared to a smooth tube. Vipertex® flat rolled patterns provide increased surface area and can add additional heat transfer, as well. Using Vipertex® as part of your existing plant expansion strategy can help you:

- Realize revenue from new capacity faster than a Greenfield site

- Preserve capital for other investment opportunities

- Use less energy per unit produced

- Payback for these enhanced tubes is typically less than 18 months

Improved Burst & Collapse Performance of Vipertex® Enhanced Tubes

Vipertex® tubes are welded from pre-textured strip, which is engineered to provide enhanced heat transfer. A collateral benefit of this texture is a strengthening of the material, which leads to a stronger tube. More homogeneous properties are present since Vipertex® tubes are annealed after the surface pattern is imparted. Burst and collapse pressure test results have demonstrated an approximate 20% improvement as referenced in the tables below.

| Sample | Plain, Smooth Tube | Vipertex® Pattern 1EHT Tube |

|---|---|---|

| 1 | 6,787 | 10,567 |

| 2 | 6,833 | 10,503 |

| 3 | 6,726 | 10,676 |

| Average Burst Pressure | 6,782 | 10,582 |

| Sample | Plain, Smooth Tube (Estimate) | Vipertex® Pattern 1EHT Tube |

|---|---|---|

| 1 | 2,669 | 3,340 |

| 2 | 2,669 | 3,842 |

| 3 | 2,669 | 3,901 |

| Average Collapse Pressure | 2,669 | 3,694 |

Pattern Optimization for Specific Applications

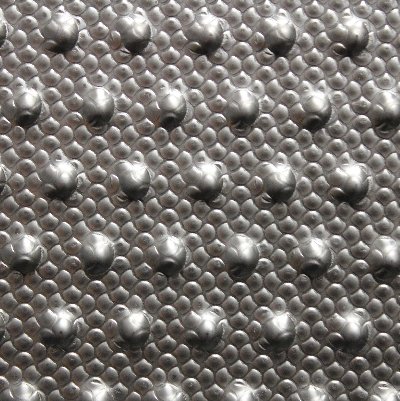

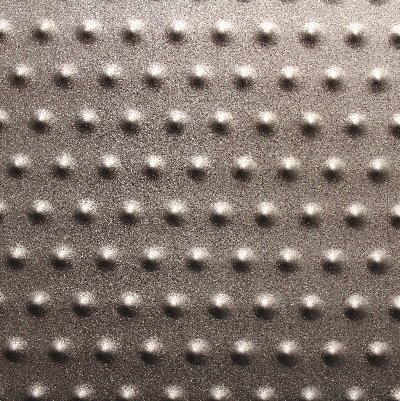

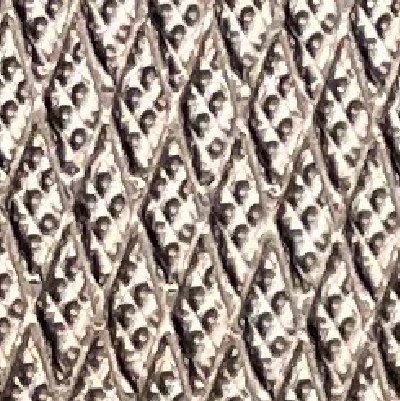

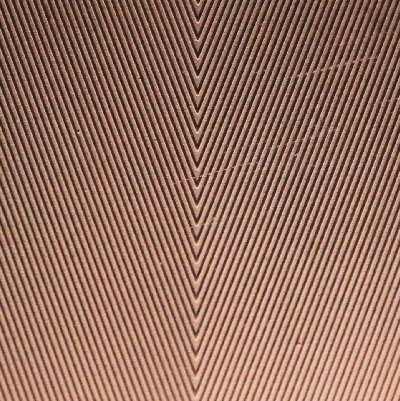

Vipertex® enhanced surfaces are produced in a selection of patterns, which were developed with specific purposes in mind.

- For most applications, our 1EHT surface will provide the best solution. It has been engineered to provide enhanced thermal transfer through increased surface area, in addition to surface patterns that promote turbulence and nucleation sites.

- 2EHT provides a surface absent of dimples to accommodate applications requiring simpler geometry, as in the case of very small diameter tubes.

- Single phase flow studies and bundle testing studies performed at HTRI® for 1EHT and 2EHT tubes.

- Our new herringbone (HB/EHT), helix (HX/EHT), and 5EHT patterns are engineered surfaces that are optimized for two phase flow applications.

It is possible to accommodate minor adjustments to these patterns to optimize them for your specific application. If it becomes important to develop a completely unique solution that goes beyond adjustments to an existing Vipertex® pattern, it would have to be reviewed as a development project with adequate volume associated with the opportunity to justify the development costs.

Explore related applications by clicking on these links for more information.