Take Tube Technology to the Next Level

The Vipertex® Vipertube® line is a family of tubes utilizing the advantages of Vipertex® enhanced surfaces. Using ASTM specifications, Vipertube® is manufactured to the highest level of quality in order to produce high-pressured tubing. Since every application is different, Vipertube® can be customized to meet your needs – including a variety of materials, alloys and sizes, electro-polishing, bending, and coiling capabilities.

Vipertube® outperforms, and provides significant advantages over, standard smooth tubes. When you need to enhance the heat transfer performance of your process application, there’s one name you need to specify: Vipertex® Vipertube®. A revolutionary metal surface technology, Vipertex® features a patented enhancement process that dramatically improves heat transfer performance.

Vipertex® Enhanced Heat Transfer Tubes

Enhancement of heat transfer using the Vipertex® Vipertube® line is produced from a combination of secondary flow generation, increased turbulence, boundary layer disruption, increased heat transfer surface area and an increased number of nucleation sites; all leading to an enhanced heat transfer performance for a wide range of conditions.

Under many conditions, the Vipertex® Vipertube® line can recover more energy and provide the opportunity to advance the design of many heat transfer products. Enhanced heat transfer tubes are widely used in order to reduce operating cost and create a smaller installation footprint.

The Vipertex® Vipertube® line includes:

Twisted Tape

Coil

U-Tubes

Finned Tubes

Available Materials & Alloys

The Vipertex® Vipertube® line is available in the following materials and alloys, shown in the table, below.

Combining any of these materials with a Vipertex® enhanced surface pattern, which is then welded into a tube, will help you optimize the performance of your heat exchanger design.

| Material | Description | Configuration | Enhanced Surface Options | Alloys | Size Range | Certifications |

|---|---|---|---|---|---|---|

| Stainless Steel | Stainless steel is the most popular choice for most industrial applications and those requiring the handling of food products or other applications where sanitary conditions need to be maintained. | Welded | 1EHT, 2EHT, 3EHT, 4EHT, 5EHT, HB/EHT | 304(L), 316(L), Other Austenitics: Duplex and Ferritic Alloys | 0.375″ – 1.5″ (9.5mm – 38mm) OD | ASTM 1098, ASME Code Case |

| Copper | Copper has excellent thermal transfer properties inherent to the metal and can stand up to a number of corrosive applications. | Welded | 1EHT, 2EHT, 3EHT, 4EHT, 5EHT, HB/EHT | C122 and others | 0.375″ – 1.5″ (9.5mm – 38mm) OD | ASTM B1040 |

| Titanium | Titanium is ideal for a number of applications where corrosive agents are involved and temperatures can be elevated. It is well suited for high chloride applications. | Welded | 1EHT, 2EHT, 3EHT, 4EHT, 5EHT, HB/EHT | Grade 1, Grade 2 | 0.375″ – 1.5″ (9.5mm – 38mm) OD | |

| Carbon Steel | Carbon steel provides strength and is low-cost with good thermal transfer properties inherent in the metal. It has limited application with corrosive agents. | Welded | 1EHT, 2EHT, 3EHT, 4EHT, 5EHT, HB/EHT | 1008/1010 and others | 0.375″ – 1.5″ (9.5mm – 38mm) OD | ASTM A1120 |

| Aluminum | Aluminum provides inherently good thermal transfer and reasonably good corrosion resistance in heat exchanger applications. Alloy 3003 provides excellent overall utility. Slightly better corrosion protection is obtained with 5052. | Welded | 1EHT, 2EHT, 3EHT, 4EHT, 5EHT, HB/EHT | 3003, 5052 and others | 0.375″ – 1.5″ (9.5mm – 38mm) OD |

Vipertex® Enhanced Surfaces

Vipertex® enhanced surfaces are designed to promote thermal transfer. These engineered surfaces can be welded into tubing or used in flat applications. Vipertex® offers enhancements engineered to your specific application. Enhancements can be applied to one or both sides of the surface.

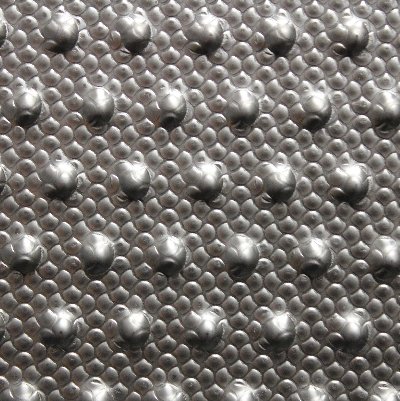

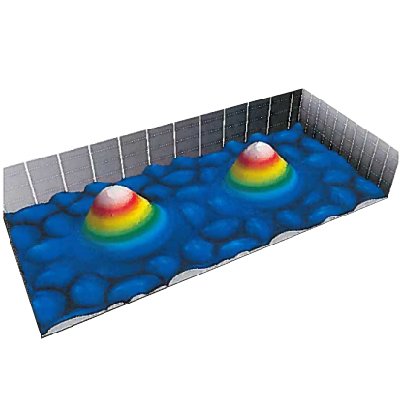

1EHT

For most applications, our 1EHT surface will provide the best solution. It has been engineered to provide enhanced thermal transfer through increased surface area. Additionally, the multiple surface patterns promote turbulence and nucleation sites. Modifications to surfaces can be done for special orders.

1EHT Surface

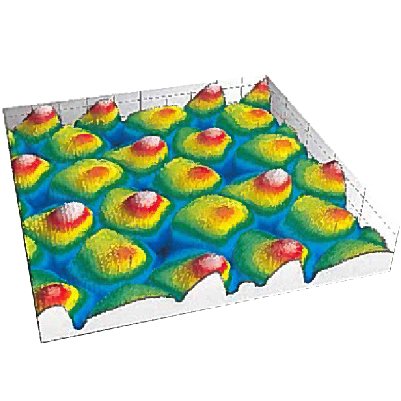

3D Rendering of the 1EHT Surface

2EHT

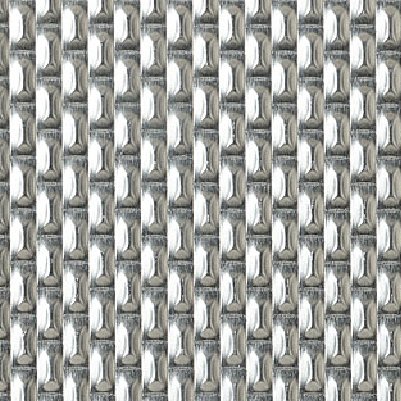

Vipertex® model 2EHT provides a surface absent of large dimples to accommodate applications requiring simpler geometry as in the case of very small diameter tubes.

2EHT Surface

3D Rendering of the 2EHT Surface

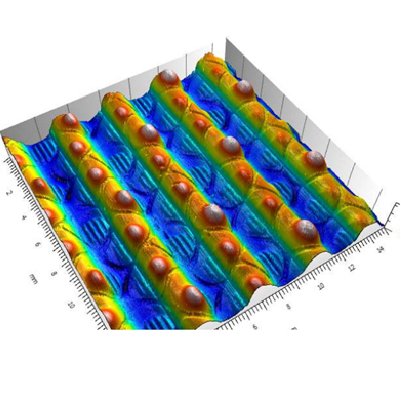

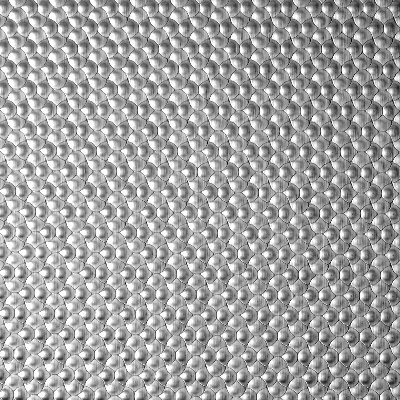

3EHT

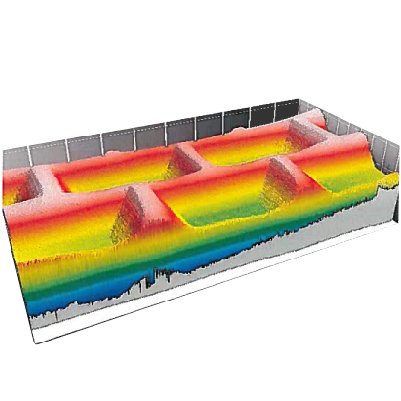

Vipertex® model 3EHT surface produces an 8.9% surface area increase when compared to flat surfaces.

3EHT Surface

3D Rendering of the 3EHT Surface

4EHT

Vipertex® model 4EHT provides an impressive 25% increase in surface area.

4EHT Surface

3D Rendering of the 4EHT Surface

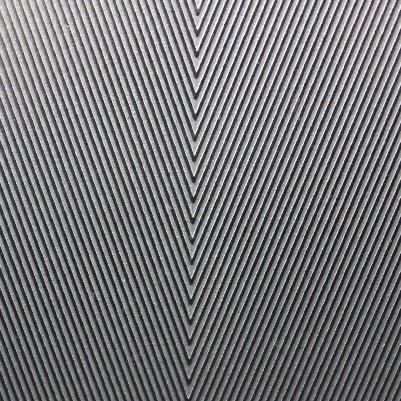

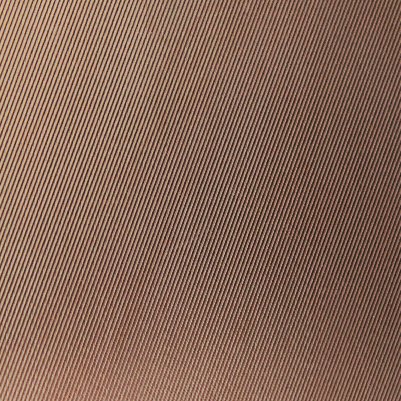

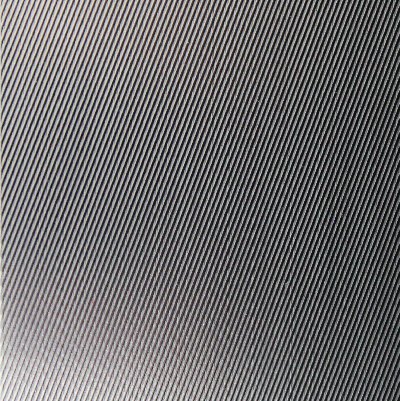

Herringbone and Helix

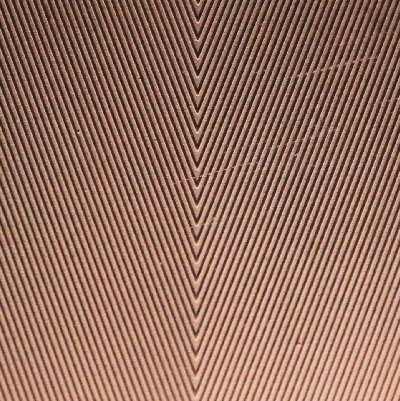

Our new herringbone (HB/EHT) and helix (HX/EHT) engineered surfaces are optimized for certain two-phase tube applications. Multiple patterns are also available.

HB/EHT in Copper

HB/EHT in Stainless Steel

HX/EHT in Copper

HX/EHT in Stainless Steel

Explore related applications by clicking on these links for more information.