Benefits of Micro Texturing

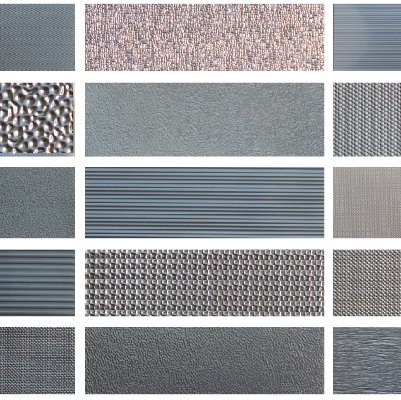

Rigidized® Metals’ Contrarian Micro Texture line continues to develop new stainless steel and other high performance metal products for the architectural market. Further study of the properties of stainless steel have revealed astonishing benefits to the environment that also translate into improved operating costs for building owners. This page will highlight the benefits of micro textures on stainless steel and other metal alloys.

Reduce Costs

Rigidized® Metals has a philosophy of helping building professionals select materials that will last the useful life of the building with little or no maintenance. This usually results in the least long term cost to the building owner. The Rigidized® Metals’ line of Contrarian Micro Textures offer durability, and long lasting products with naturally-cleaning properties, which reduce cleaning and maintenance costs to the building owner. These products will thus last the lifespan of the building itself.

Learn more here.

Acquisition Costs Put in Perspective

Stainless steel buildings are quite durable.The dome of the Chrysler building in New York is a great example. Having only been cleaned twice since its construction in 1929, there is no doubt that it will continue to perform its duties until such time as the building is taken down. Before the reader dismisses stainless steel as a building material because they do not intend to be around as long as the Chrysler building, there is much more to consider.

Learn more here.

Reduce Damage Losses

While a building owner’s risk management costs are primarily a function of insurance premiums, smaller damage claims are often absorbed by the owner because the deductible is not met or the owner does not wish to trigger a premium increase. Stainless steel building panels can help the owner avoid risk in the first place and potentially lower costs to remediate damaged panels.

Stainless steel has superior fire resistance to more commonly used construction materials, including metals like aluminum, copper, and zinc. Since stainless is stronger and does not depend on coatings to protect the surface, it has a measure of hail resistance. Paint from tagging or graffiti is easily removed, particularly from rolled-in stainless steel finishes.

Learn more here.

Reduce Maintenance Expenses

The extraordinary durability of stainless steel means very little maintenance is required to preserve the original appearance, provided a suitable grade is used for the building’s environment. Finish selection also plays a major role in maintenance costs. Building owners are best served when designers take this into consideration.

Learn more here.

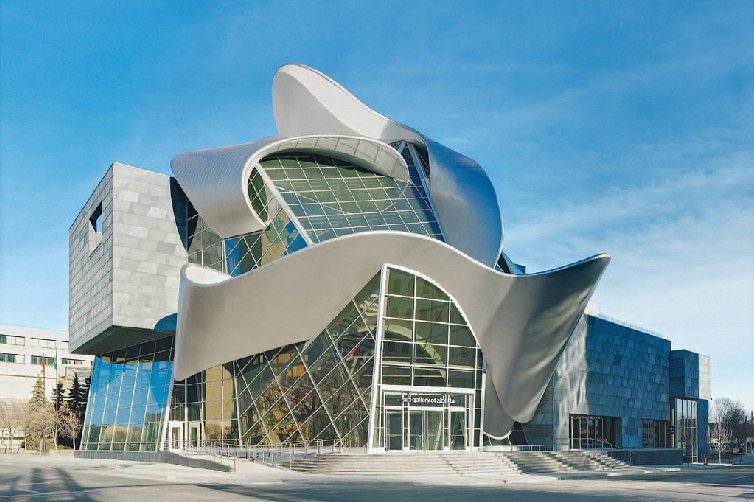

Maintain Property Values

A stainless steel building has an unmistakably high-end appearance that lasts indefinitely with very little maintenance. Since stainless steel buildings are cheap to operate and look great over the long haul, it stands to reason the owner will command a higher price when the building sold. However, there is more to the story than just the selling price. A building that retains its high end appearance over time attracts tenants, customers and employees, which maintain the owner’s revenue stream.

Learn more here.

Life Cycle Costing

While stainless steel costs a bit more up front, it returns on that investment in many forms for as long as the building stands. This paper serves to aid in the process of determining variables to consider when evaluating different materials on a life-cycle basis.

Learn more here.

Save Energy

Reduce Climate Change & Other Environmental Benefits

Rigidized® Metals has a philosophy of helping building professionals select materials that will last the useful life of the building with little or no maintenance. This usually results in the least long term cost to the building owner. In addition, significantly less harm can be made to the environment by using long life materials as opposed to more commonly used materials that require maintenance and replacement. Specifically, our portfolio of high performance engineered architectural metals serves this philosophy well. Beyond offering sustainability (when properly specified and installed) these metals are, by their nature, environmentally “green” materials.

Thermal & Solar Reflectance of Stainless Steel

Since the chromium oxide layer that naturally develops on the surface of stainless steel is thin and invisible, it is a near-perfect solar and thermal reflector. This translates to energy savings in hot, as well as cold, climates, and a reduction in the heat island effect, therefore mitigating climate change. This paper deals with the basics of thermal and solar reflectance and provides the reader with information about test procedures and results for stainless steel compared to other materials.

Learn more here.

The Insulation Value of Stainless Steel

The remarkable thermal properties of stainless steel result in R value for the metal itself, thereby lessening the demands of panel insulation systems to meet design criteria. More importantly, it gives designers an opportunity to improve the energy efficiency of buildings, given a set panel and an insulation system. This document provides information regarding the contribution stainless steel makes toward insulating buildings.

Learn more here.

Stainless Steel Buildings Combat Climate Change

Since the chromium oxide layer that naturally develops on the surface of stainless steel is thin and invisible, it is a near-perfect solar and thermal reflector. This translates to an energy savings in both hot, as well as cold, climates, and a reduction in the heat island effect, therefore mitigating climate change.

Learn more here.

Extraordinary Recycling Efficiency

Approximately 60% of the world’s stainless steel production contains recycled material. In the United States the average is closer to 75% of all stainless steels. Some products will have a lower recycled content while others will be higher, based on melting location, grade and product form. Please contact a Contrarian Metal Resources Product Consultant for details of the recycled content specific to your project.

Learn more here.

LEED® & Green Globes Design™ Points

There are a number of areas where the use of our materials can contribute to the accumulation of LEED® (Leadership in Energy & Environmental Design) and Green Globes Design™ points. It is best to contact us for assistance in predetermining exactly where these opportunities are for each given product, application and project location.

The Superior Durability of Stainless Steel

Stainless steel buildings have been around for nearly 100 years without showing signs of degradation. Perhaps the most widely known example of this is the dome atop the Chrysler building. Built in 1929, it has only been cleaned twice and remains in excellent condition without any expectation that it will need to be replaced. From an environmental standpoint an architect or building owner can count on this material to last the useful life of the building. Combining this fact with energy savings, heat island mitigation, impressive recycling statistics and other environmental benefits, it is truly a sustainable product that is good for the planet.

Learn more here.

Eliminate Biocide Runoff

As more common building materials break down under exposure to the elements, stainless steel does not, assuming the proper grade is used. A considerable amount of lead continues to find its way onto buildings, primarily in the form of lead-coated copper. Lead, paint coatings, and even copper and zinc for that matter, oxidize in building envelope applications. Runoff from these oxides can be introduced to the ground and nearby wetlands and water tables. Stainless steel poses no risk in this area, making it a sensible choice particularly in environmentally sensitive locations.

Learn more here.

Why Low Glare Stainless Steel Matters

Stainless steel is an extraordinary building material. It is attractive, energy efficient, durable, and is arguably the most sustainable choice among metals with which we build buildings. Traditionally it has been used in construction for interior elements. Today, there has been a substantial increase in its use as exterior cladding material. Part of this recent increase is usage can be attributed to the development of InvariMatte® stainless steel which allows this material to be used in a large surface areas in glare-sensitive environments.

Learn more here.

Naturally-Cleaning Stainless Steel Finishes

For Applications Requiring the Maintenance of Clean Surfaces

Perhaps the best performance feature of textured metal comes from the use of hydrophobic stainless steel surfaces that resist the accumulation of dirt, maximizing solar reflectance and minimizing the need to clean the roof or façade. Accumulated surface soil absorbs more solar radiation than it reflects. It is therefore important to keep the stainless steel clean in order to maintain maximum solar reflection. The use of a hydrophobic surface will delay, if not eliminate the need to clean the building’s surface.

While applications other than building envelopes do not necessarily require efficient solar energy reflection, there are numerous opportunities for increased efficiency from the use of hydrophobic stainless steel surfaces. Uses in food and chemical processing, heat exchangers, restaurant equipment; simply any case wherein it is desirable to have a surface stay cleaner longer and be more readily cleaned when the time comes to do so, can benefit from a hydrophobic texture.

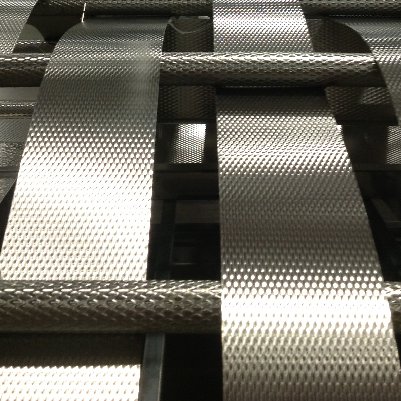

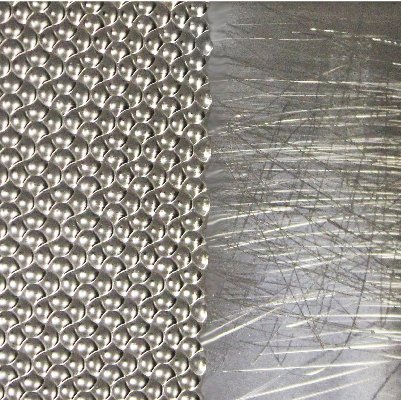

A hydrophobic surface, as defined by the angle of incidence of droplets, repels water and has low surface tension, which tends not to attract contaminants and rinses cleanly. A permanent hydrophobic surface is achieved in stainless steel by micro-texturing the surface of a mill-finished coil with a surface pattern that has features smaller than the diameter of a human hair. Rigidized® Metals produces several such hydrophobic stainless steel finishes, ranging from dull to bright.

Learn more here.

Explore additional benefits of engineered surfaces.