Economic Sustainability

Rigidized® Metals’ products will last the useful life of most applications, with little or no maintenance required, leading to lower long-term costs due to maintenance and replacement.

Environmental Sustainability

Textured stainless steel is playing an important role in sustainable design and alternative energy evolution.

Social Sustainability

Rigidized® Metals is proud to share our expertise and collaborate on initiatives that are inclusive, equal and sustainable to our local community and the world as a whole.

Economic Sustainability

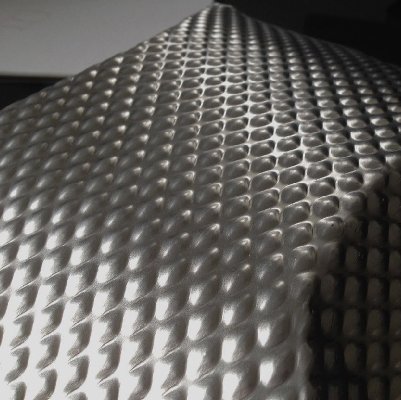

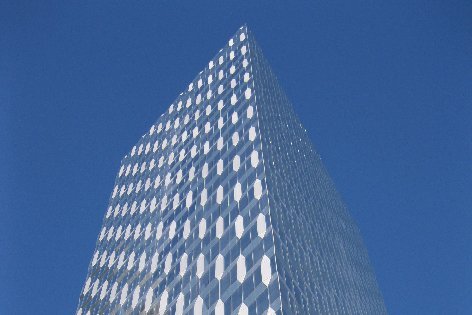

Rigidized® Metals’ engineered surfaces resist dents, hide scratches, and hide fingerprints, making them last longer and look cleaner than ordinary metals. Ultimately, the most environmentally friendly materials are corrosion resistant and durable, and stainless steel facades have been known to provide up to 80 years of service life in architectural projects without appearance deterioration or metal replacement. When properly selected, fabricated, and maintained, it should last the life of the structure. Products made from Rigidized® Metals materials simply look better for longer, require less effort to maintain, and are made from fewer raw materials.

Energy Savings

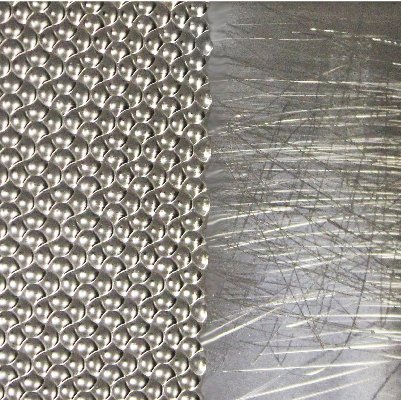

Adding an engineered surface to metal can usually reduce weight, which saves energy required to produce a certain module size for a part. Additionally, the impressive, solar reflectance of some of our engineered architectural panel surfaces reflect the majority of the Sun’s radiation back into space without converting to infrared energy. This puts less burden on HVAC systems. Also, in the case of stainless steel and titanium, insulation value is provided by the metals themselves, which also contributes to energy savings. Heat exchangers can benefit from enhanced surfaces to make HVAC and industrial equipment more efficient.

Weight Reduction

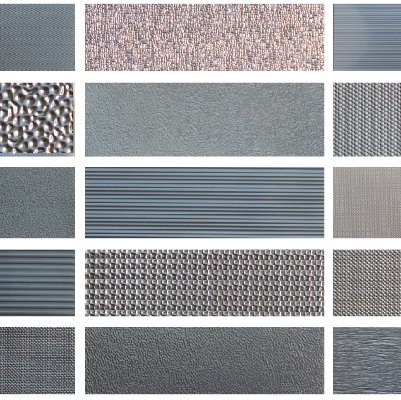

When Rigidized® Metals’ deep textured metal is used in place of flat metal, lighter gauges can be substituted, reducing weight and saving metal without sacrificing strength. Further, thinner, lighter components make vehicles more efficient in their operation. Rigidized® Metals’ products are up to 75% stronger than ordinary sheet metal, allowing for down-gauging, which results in less raw material consumption, thus saving money and precious environmental resources.

Durability

In addition to the aesthetic appeal that deep texturing provides, the strength and durability of these materials helps reduce maintenance costs, ultimately saving time, resources and money. The deep texturing of metals makes the surface appear damage-resistant, as scratches, dents and dings become far less visible on the textured surface.

Processing Efficiency

Metal surfaces can be designed to reduce friction, making the flow of processed goods much more efficient. There are times when greater friction of a metal surface can improve efficiency, and surfaces can be engineered to perform that function, as well. The increased surface area of Rigidized® Metals’ deep textured patterns reduces surface tension and friction for processing machinery in industrial markets. Heat exchangers can benefit from surface designs that promote the efficiency of these units, thereby reducing costs.

Reduced Maintenance

Metal products can be designed to contribute to the ease of maintenance. Hydrophobic surfaces are very easy to clean. In exterior building applications, they are naturally cleaning and often require no more than removal of debris. Further, a properly specified metal material can perform its function without relying upon any coatings at all. This eliminates repainting or refinishing.

See what the RGDZRs are doing to impact economic sustainability for Rigidized® Metals.

Explore additional benefits of Rigidized® Metals’ engineered surfaces.